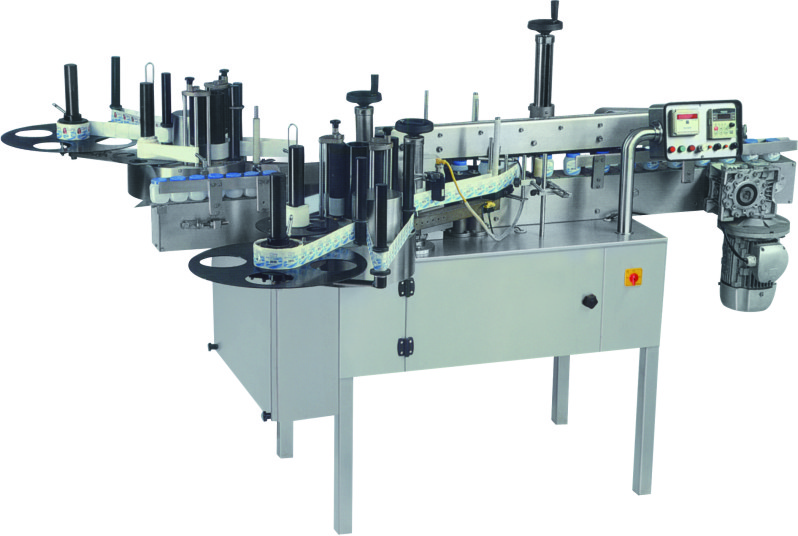

Double Side Sticker Labeling Machine

Being a reputed manufacturer of the double side sticker labeling machine, we boast of having one of the most excellent and performance qualified labeling system. The product model NKSAL-120D is a synchronized and user friendly system for good quality labeling operation. Intrinsic speed indicator and accurate label dispensing are some of the salient features of the device.

Salient Feature of Machines of Double Side Flat Bottle Sticker Labeling Machine:

Double Side Sticker labeling machine has following inbuilt feature.

- S.S. 304 Constructions.

- Facility to incorporate the Batch coding printing like Inkjet printing or hot foil coding & contact coding.

- In built Speed Indicator & Counter

- No Change Parts for Label size, Feed Worm and Pocket System required for a change in product size

- Single Pot On-line Speed Variation control

- Synchronized speed of Label Dispensing, Conveyor and Top Hold Belt System

- Virtually Maintenance free machine

- Easy to change label application height

- User Friendly Label Placing Adjustments

- Suitable for On-Line Inkjet and Contact Coding System

- Suitable for Partial, Full Wrap Around and Overlap Labeling

- Built In A.C. Variable Frequency Drive System.

- Fully Stainless Steel finishes Machine.

Machine Safety Feature:

- No Label – No Container

- No bottle at in-feed, Machine stops.

TECHNICAL SPECIFICATION:

| Label Height | 8 mm to 70/90/120/150 mm Standard* |

| Label Length | 12 mm Minimum |

| Label Roll Dia. | 300 mm |

| Core Dia. | 75/76 mm |

| Gap Between two Labels | app. 3 mm |

| Product Size | Product Size : As per customers requirements*Feed Worm and Pocket System require for change in Product Size for Special Machine |

| Electrical | 220 VAC Single Phase Power Supply (50/60 Hz) |

| Power | Power: 2.0 Amps. |

| Capacity | 0.75 Kw |

| Speed | Up to 90 to 100 Labels per minute depending on product and Label Size. The speed is also depending on stable movement of the product on machine conveyor at higher speed. |

| Conveyor height | 830-875 mm* |

| Overall dimension | 2280 mm(L) X 1500 mm(W) X 1500 mm (H) |

| Machine Direction of Movement | Left to Right from the operator side |

ADD On Features of Double Side Sticker Labeling Machine:

- Label Roll Empty – Machine Stop System with Alarm

- Missing Label in Roll – Machine Stop System with Alarm

- Special Label Sensor for sensing Transparent Film Labels which does not have any sensing mark on it.

- Toughened Glass or Acrylic Safety Cabinet for Machine

- Tower Light showing the machine status / operation

- Special Sensing system for checking missing label on product

- Vision System for checking Barcode, presence or absence of Coding or pharma code on labels

- Vision System for checking various details on labels

- Online pneumatically operated product rejection system.

Video of Double Side Sticker Labeling Machine: